Sawmill Frequently Asked Questions

Why is a sawmill being constructed on this site?

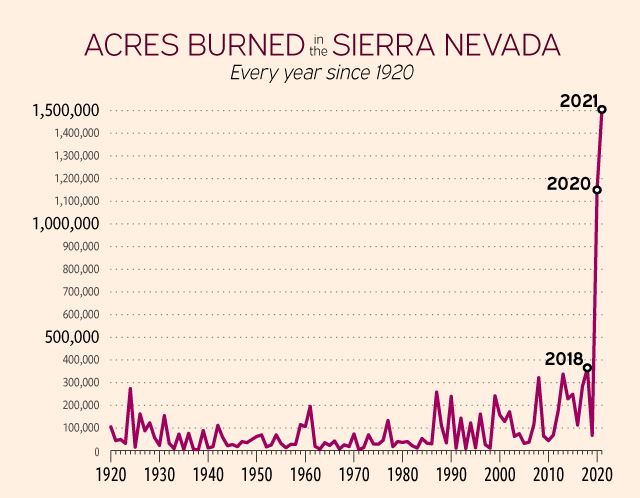

Beginning in the early 1900’s, total fire suppression combined with clear-cut logging of mature stands was the US Forest Service’s primary management practice. The unintended consequence is that today the Sierra Nevada has far too many trees competing for too little soil and water in a warming environment. This combination has led to overgrown, malnourished, diseased and dry forests that, when sparked, create catastrophic wildfires.

Source: Sierra Nevada Conservancy.

TFP is part of the solution by providing a market for both fire killed as well as thinned timber to reduce fire fuels, including selective tree reductions across the Tahoe basin and broader Sierra Nevada. We are not a logging enterprise, but we provide loggers a necessary site to which they can deliver both green thinnings and salvaged timber.

Our operation will initially support cleanup efforts on the Caldor and Tamarack fires. Our first logs are arriving from Sierra-at-Tahoe ski resort, where critical cleanup work is occurring to allow the mountain to safely reopen for recreation in the 2022/2023 season, providing continued direct employment for up to 800 Sierra employees, plus benefits to the local El Dorado County economy.

Recently, the US Forest Service commented on the arrival of TFP in our region: “The Forest Service encourages expansion of sustainable value-added businesses and markets for byproducts of forest restoration and hazardous fuels reduction projects. It’s great to have this facility coming online and adding to the suite of businesses that contribute to the restoration economy.”

Prior to entering a lease with Washoe Development Corporation in July 2022, multiple other sites near the Lake Tahoe Basin were researched over a two-plus year period. Other sites were deemed unfeasible for various reasons: land ownership difficulties, multi-year or impossible permitting requirements, and lack of commercial/industrial zoning, among others.

Isn’t taking trees out of the forest bad for the environment?

The clear-cut logging practices of the 19th and early 20th century earned the timber industry a bad reputation. But today in the United States, most tree removal relates to “fuels reduction” projects as part of sustainable forestry, and post-fire cleanup, with support from the scientific and environmental community. Sustainable forestry is the practice of removing some trees, underbrush, and ladder fuels, leaving the remaining trees with less competition for light and water, and less dry brush that can fuel catastrophic fires. Larger trees, with less competition for water, are more fire and insect resistant. Before 1850, the Sierra Nevada tree population was a fraction of today’s, but with much larger, healthier trees.

Many in the scientific community advocate for sustainable forestry and fuels reduction as the best hope for saving our forests and the species and communities that rely upon them. Note: none of these groups have specifically endorsed Tahoe Forest Products.

~~

Ecologists at UC Berkeley and UC Davis note “More than a century ago, Sierra Nevada forests faced almost no competition from neighboring trees for resources. The tree densities of the late 1800s would astonish most Californians today. Because of fire suppression, trees in current forests live alongside six to seven times as many trees as their ancestors did — competing for less water amid drier and hotter conditions. The study, published in the journal Forest Ecology and Management, suggests that low-density stands that largely eliminate tree competition are key to creating forests resilient to the multiple stressors of severe wildfire, drought, bark beetles and climate change.” (1)

~~

The Nature Conservancy, the largest environmental non-profit in the United States, promotes “ecological forestry.” “Ecological forestry has two main ingredients: careful and targeted removal of forest fuels—thinning of smaller trees and shrubs in strategic, accessible areas where it is needed most and will have the least negative impact on sensitive species—plus implementation of prescribed fire and managed wildfire as a natural process where it is safe to do so.” (2)

“It can take decades if not hundreds of years for large patches of severely burned forests to recover; some of the forests may be permanently converted to shrub fields if the sizes of high severity patches are very large.”

“In 2019, The Nature Conservancy, a global conservation leader, and Bain & Company, a top-ranked management consulting firm, partnered to evaluate the role marketable wood products sourced from smaller-diameter trees (such as wood used for bioenergy or lumber) can play in accelerating the restoration of California’s fire-prone forests to promote forest health and resilience and reduce the risk of high-severity wildfire.”

“Based on a systematic evaluation of more than 40 end markets (using criteria related to each product’s technical feasibility, readiness, environmental impact, and economic viability), Bain concluded that the expanded use of existing technologies (such as bioenergy and sawmills) offers the most promising means of accelerating forest restoration.” (3)

~~

At the 2023 United Nations COP28 conference (aimed at combating climate change), the United States and 16 other countries committed to the increased use of timber products in construction.

“Recognizing that wood from sustainably managed forests provides climate solutions within the construction sector, we commit to, by 2030, advancing policies and approaches that support low carbon construction and increase the use of wood from sustainably managed forests in the built environment. Such policies and approaches will result in reduced GHG emissions, and an increase in stored carbon.”

Convening Chair of the ISFC Dr. David Brand said, “The construction sector and the built environment accounts for more than a third of global emissions and it is critical that countries move quickly to lower carbon emissions and increase stored carbon by using far more timber in buildings. We also need to replace plastics with fibre based products and bring sustainably produced bio-based materials at scale into textiles and fuels and pharmaceutical production systems. We are pleased that the International Sustainable Forestry Coalition is specifically referenced in the supporting documentation for this announcement.” (4)

~~

According to the World Economic Forum, “When sourced from sustainably managed, climate-smart forests, biobased buildings can be hugely instrumental in combating climate change, driving investment back into forests while simultaneously creating a carbon sink in the built environment.”

“So, while traditional buildings made from concrete and steel are expected to produce around 2,000 metric tons of CO2 emissions, an equivalent timber building can match this in carbon storage.”

“And, not only does timber construction benefit the environment by helping to cut down carbon emissions by substituting for carbon-intensive materials, it can also create demand for wood from sustainable well-managed forests, thereby paying for management that reduces the likelihood of forest fires and providing habitat for wildlife.” (5)

~~

Concerned about old growth forests? So is TFP.

US Forest Service research indicates “Since 2000, wildfires resulted in a decrease of an estimated 2.57 million acres of mature and 712,000 acres of old-growth forests on National Forest System (NFS) and BLM lands. Insects and disease caused a decrease of 1.86 million acres of mature and 182,000 acres of old growth. Tree cutting by the BLM and Forest Service resulted in a decrease of 214,000 acres of mature forests and 9,000 acres of old growth.” (6)

So, fire and disease drove 96% of mature and old growth forest loss since 2000. Scientists broadly agree that sustainable tree removal reduces the threat of fire and results in healthier remaining trees. Sustainable forestry is our best hope to protect mature and old growth forests.

~~

Concerned about endangered species? So is TFP.

The US Fish and Wildlife Service has concluded “Large scale, high severity wildfires are the largest threat to California spotted owls and Mexican spotted owls. These fires displace owls into other areas and force them to establish new territories often in lower-quality habitat.”

“The other major threat to spotted owls is the barred owl. Northern spotted owl populations are in serious decline due to competition from the invasive and non-native barred owl, along with past and ongoing habitat loss.” (7)

Long-time observers of the forestry industry in California will know concern for the spotted owl was the death knell for most Sierra Nevada sawmills in the 1980’s and 1990’s. Today, the best hope we have for protecting the spotted owl is a thriving sustainable forestry industry in the Sierra.

~~

In addition to the environmental benefits of our existence, we provide good paying jobs and business to hard working sawmill, logging, and transportation families that live in and care deeply about our forests and rural communities.

(2) https://www.scienceforconservation.org/assets/downloads/EcologicalForestry_2019rev.pdf

(3) https://www.scienceforconservation.org/assets/downloads/tnc_AFR_v9.pdf

(5) https://www.weforum.org/agenda/2023/01/sustainable-timber-core-building-material

(6) https://www.fs.usda.gov/sites/default/files/fs_media/fs_document/MOG-Threats-Intro.pdf

What is the history of this site?

Prior to the arrival of European settlers, this land and Clear Creek were part of the Washoe Tribe’s homeland. In the 1860’s, at the time of the Comstock Lode discovery, this site was acquired by the Carson and Tahoe Lumber & Fluming Company, the original logging and lumbermill operation founded by DL Bliss. Bliss’ company shipped lumber by train from Glenbrook to Spooner Summit, where lumber was transferred to flumes adjacent to Clear Creek and floated down to the bottom of the creek, where our site sits today. Pictures from the 1870’s near and on this parcel depict hundreds of acres of stacked lumber waiting to be shipped to Virginia City. In 1908, the Federal Government purchased the broader 229-acre parcel on behalf of the Washoe Tribe, and the Tribe has owned the land since. The Tribe approved this parcel for commercial development in 2008, and TFP is proud to return it to the historical use in a unique partnership with the Tribe.

According to the Truckee Donner Railroad Society, “The flume terminated in a large lumber yard at the south end of Carson City. The yard was located a half mile south of today’s junction of Highways 50 and 395. Extending for nearly a mile in length and a half mile in width, the yard provided vast amounts of lumber storage.”

The timber cut then was almost entirely pine used, as is evident in the below photograph, for pit props in the Virginia City mines. Unfortunately, much of what grew back in the Basin was white and red fir, an aggressive pioneer species but not as fire resistant as pine nor as long-lived.

What is the site layout?

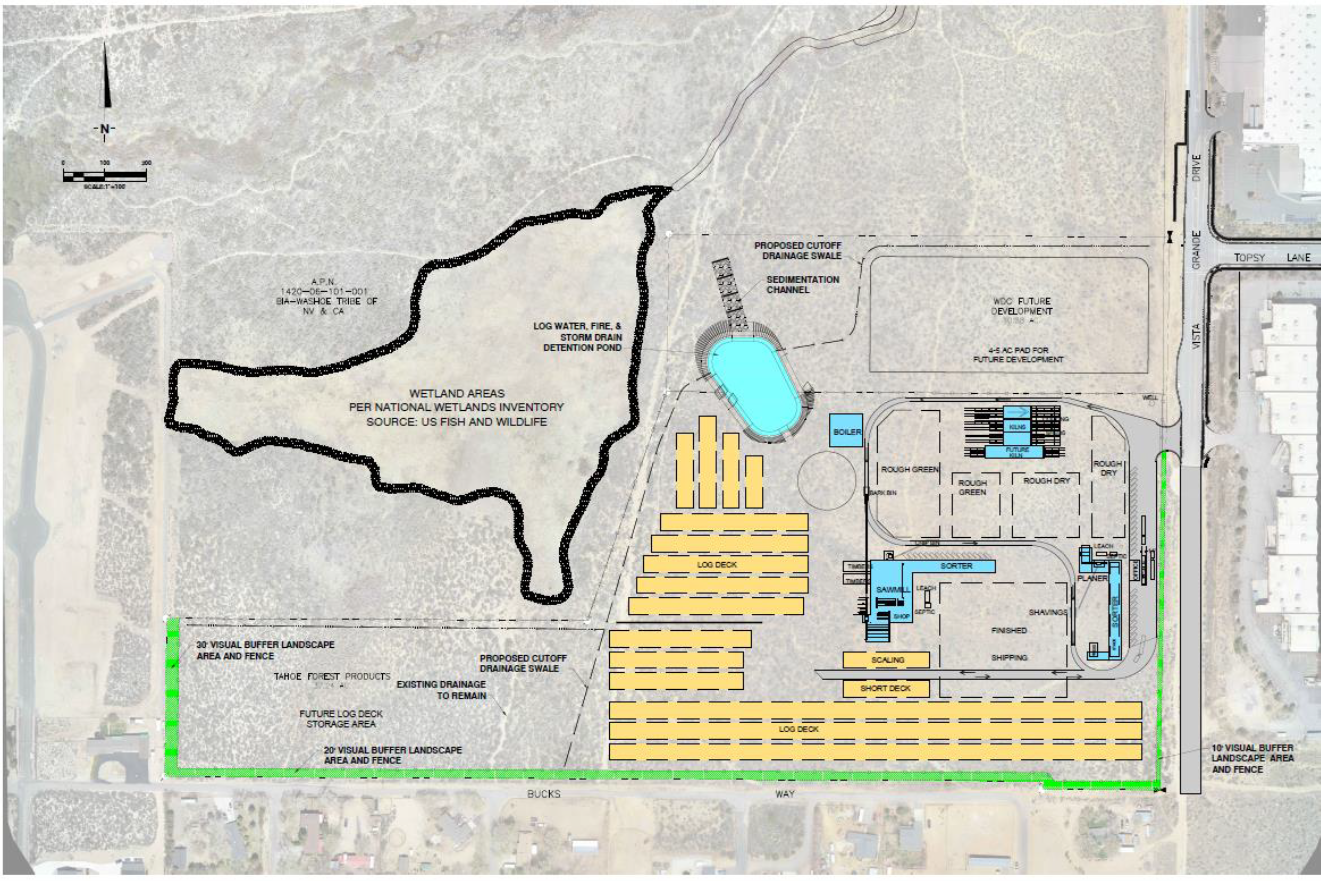

TFP’s lease area and building layout is approximately represented in the below image.

What will the site and buildings look like?

TFP has signed a long-term lease with the Washoe Tribe for 37 acres of land. Approximately 25-30 acres will be used to store stacked logs (“log decks”), while about 10 acres will be developed for mill operations. Most of the southern and western borders of the site will be log storage areas, while the center and northern, and eastern sections of the site will be used for mill operations.

To the extent possible, the building facilities will blend into the local landscape, using colors similar to those of the adjacent retail buildings along Vista Grande Boulevard.

The log decks will be approximately 25 feet tall, and we expect the tallest building structures to be about 40 feet tall.

TFP is actively researching additional options to enhance the appearance of our site, including grading techniques and landscaping with trees and native vegetation along the southern and western borders. We are engaging with multiple residential community members to design an attractive visual barrier between our site and Bucks Way to our south, which may include a wall, berm, fence and/or multiple forms of landscaping. If you are an immediate neighbor of our site and wish to participate in this conversation, please contact us at [email protected].

What products will the sawmill produce?

Our log supply will primarily be the pine, fir and cedar species found in our portion of the Sierra. ,While we will first install machinery for the large logs that are coming off the fires we plan to add a small-log line in 2023 so that we can accept small logs from thinnings, which is essential if we are to protect the forests from further catastrophic fire. This will include logs with small-end diameters down to six inches.

TFP will manufacture dry “dimension” lumber for construction markets, green fence posts and rails from the fir for treating, cedar siding, and boards and factory lumber from the pine, the pine will used for windows, doors and trim. We will also produce pallet lumber for local plants as well as some landscape and heavier timbers. TFP will actively seek local markets for the mill’s sawdust, bark, and chips.

TFP does not currently intend to be an end use facility for forest biomass, though we are discussing commercial relationships with various biomass users.

TFP does not currently intend to pressure treat lumber on site, nor create wood-based products such as plywood, cross-laminated timber or fiber board.

Where will the mill's products be sold?

We expect to sell dry fir construction lumber in the local market and southern Nevada and California. Rough green fir will mostly go to Central Valley treaters, and pallet boards to local pallet plants. Pine boards will mostly go to home improvement stores, while pine and fir, from the outside of larger logs is “factory” lumber for window, door and trim remanufacturers throughout the U.S. Cedar will all be sold through local lumber yards.

How noisy will the operation be?

Standing outside a sawmill, observers usually can’t hear anything happening inside the facility. Audible noises outside will mostly include backup alarms on vehicles (the beep-beep sound), and logs being placed on a metal conveyer. TFP will use several industry best practices to control noise impacts to the neighboring community, including situating log decks so that they function as sound and visual barriers.

TFP has also engaged a sound engineer to potentially further reduce noise impacts from the site, and has redesigned certain site elements based on community feedback.

Will the operation have a smell?

Generally no, although an air-dry process used on certain lumber will occasionally cause a smell like that of a Christmas tree lot.

What is the site's construction timeline?

Site preparation including grading began in July 2022. Building construction will start in late September and machinery installation is expected to last through the end of 2022, with mill operations expected to begin in the spring of 2023.

What will the sawmill’s hours be?

Once operational, we expect the mill’s work shift is likely to run from 7:00AM to 3:30PM on weekdays. The log yard will operate from 6:00AM to 5:00PM. At some point the mill may add a second shift.

What permits are required?

The majority of regulations governing TFP’s site and facility are Washoe Tribal laws, including environmental and cultural regulations. Potential air and water impacts are subject to Federal law and those permits, and industry standard applications are being processed. Depending on the permit, TFP and/or WDC may both be applicants as lessee/operator and lessor/owner.

At the local level, TFP requires transportation ingress/egress permits from local municipalities. We have engaged a traffic engineer to help us analyze our traffic impact, which we do not believe will exacerbate local traffic conditions, particularly considering the mill’s hours will end before the start of afternoon rush hour. Between May and October we would expect to receive about four loads of logs per hour. Lumber and residual shipments will average under three loads per hour throughout the year. TFP cannot speak for the Tribe nor County entities, but we have no plans to connect roads between our site and roads directly to our south.

How will the local environment be affected?

We will be a committed steward of our site. TFP commissioned a detailed environmental study from a Reno-based firm, identifying several environmentally sensitive areas on the broader Clear Creek parcel. TFP’s entire site avoids these areas as well as additional Tribal environmentally and culturally sensitive areas. Clear Creek is an important resource for the Tribe and local community and we will protect, and hope to improve, the drainage flowing into this stream.

For the construction phase, TFP’s grading contractor has installed industry-standard water and dust control prevention measures. TFP has additionally engaged a specialized environmental protection firm to add additional protective measures and independently monitor the site for industry-standard environmental compliance. While we are making every effort to reduce impacts, some amount of dust is inevitable when a sagebrush field is graded for construction.

During production, TFP will dry certain lumber products in kilns, which will create a modest level of non-toxic emissions. These emissions will be scrubbed and will be compliant with Federal EPA requirements as well as local and state particulate limits. We anticipate our boiler to be a “minor source” by EPA standards. Our emissions impact to the local community should be minimal.

Is there added environmental risk of burned logs being on site (burned bark, fire retardant)?

As close observers of TFP’s log decks may have noticed, only the outermost one to two inches of bark tends to burn on a tree affected by wildfire. Some small amount of ash is released by the tree handling involved in decking logs. Ash in an of itself is not a harmful substance, in fact, it is commonly used in amendments for lawn and garden soils.

The primary substance used as a fire retardant in fighting wildfires has been reviewed by the EPA and approved for use by the USFS. The mixture is 85% water, 10% fertilizer, and 5% of colorants (for visibility to pilots), corrosion inhibitors, and natural clays used as thickeners. The USFS notes that accidental direct applications on humans in the past have had minor impacts, including skin irritations. If fire retardant is present in our log decks, we believe the potential environmental impacts to be negligible. The USFS also notes that smoke inhalation from wildfires has a greater health impact than fire retardant.

How will fire risk be mitigated?

Senior management at TFP has extensive experience in fire risk mitigation at sawmill facilities. TFP, like most sawmills, will “sprinkle” its log decks (think of a very large pivot sprinkler) and have significant water resources on site, including a pond dedicated to recovering and recirculating water throughout the log decks. This pond will hold three-acre feet (980,000 gallons) of water and will have both electric and back-up diesel pumps to quickly respond to any fire. The mill will also employ typical sawmill best practices, including dust capture.

Additionally, we are approaching local fire protection districts in the hope that we will be able to make service calls to our site, despite being on sovereign tribal land.

What water source will the mill use? Will the drilling of a well impact neighboring residential wells?

The Tribe, as part of its site preparation, is drilling a well near the northern border of the leased area, which is largely downslope of the residential neighborhoods to the site’s south and west.

Based on community feedback, TFP has engaged hydrologists to analyze the site’s proposed well. A preliminary appraisal suggests the well should be 400 feet, drawing on the general Carson Valley aquifer, and that it will have no effect on local shallow aquifers. Additional information will be shared with the community as it becomes available.

TFP is also exploring whether use of local municipal water sources is a practical secondary water source, though no guarantees can be made that the Tribal land can gain access to municipal water within neighboring Nevada counties.

Who are TFP’s principals?

TFP’s senior management team includes a multi-decade career sawmill designer/constructor/operator, a former General Manager at one of the largest sawmills in the Sierra, and established local investors with significant experience supporting new enterprises. TFP’s senior team has roots in the region and cares greatly about improving local forest health. The Company’s investors include board members of the UC Davis Tahoe Environmental Research Center, The Tahoe Fund, and the Parasol Tahoe Community Foundation.

What is the Washoe Tribe’s involvement in the mill?

The Washoe Tribe is TFP’s landlord, and will participate in the economics of the business. TFP will also actively encourage Tribal and local neighborhood employment at the site.

How will TFP seek neighborhood feedback regarding the site?

We will be a good neighbor, and welcome feedback from the community as our construction and operations progress. We have conducted multiple community meetings to gather feedback, questions, and concerns. We will host another community meeting once we have meaningful new information to share with our neighbors, likely in early October 2022. We additionally plan to host a community tour of our facility once it is operational.

This page will be continually updated as we receive additional questions and comments from our community. Please also check TFP’s website at tahoeforestproducts.com or Facebook page at https://www.facebook.com/tahoeforestproducts for additional news and information.